|

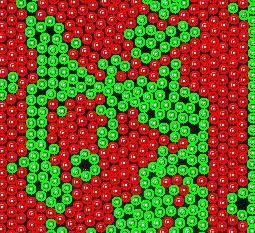

Growing of hexagonal compact domains in a granular compaction experiment.

Watch the movie

Flowing of metallic balls in a rotating drum

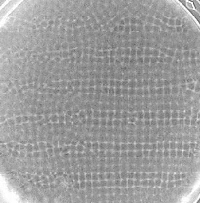

Vibrated granular layer. Watch the movie

|

About me

By chance my professional activities are combining my passions for sciences and technologies.

I’m using extensively competencies in electronics, programming, and mechanics to develop original

measurement devices for research projects and to illustrate my lectures. These competencies were

mainly developed in the framework of my hobbies: DIY electronics,

aeromodelling, mechanics, blacksmithing and bladesmithing.

Position

Lectures

- General Physics (for students in pharmacy)

- Thermodynamics (for bio-engineers)

- Waves and Quanta (for engineers)

- Techniques of Experimental Physics (for students in physics)

- Numerical tools for Soft Matter Physics (for students in physics)

Some pictures of the experiments performed to illustrate my lectures:

Research

Soft matter -

Cohesive granular materials -

Static, quasistatic and dynamical properties of granular materials -

Effect of a magnetic and electric field on a granular material -

Powder electrostatics -

Self Assembly processes -

Active materials -

Colloids

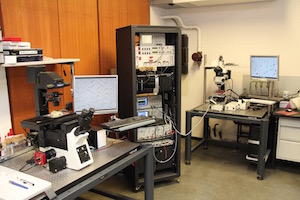

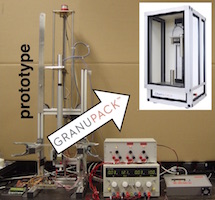

Research strategy - Our strategy to study a physical phenomenon is based on the development of original experimental set-ups to obtain original experimental results. Afterward, physical models are proposed to describe the physical mechanisms and to extract the main parameters. If needed, numerical simulations are conducted to investigate parameters which are difficult to control experimentally. Sometimes, laboratory prototypes developed to perform fundamental studies are becoming commercial instruments.

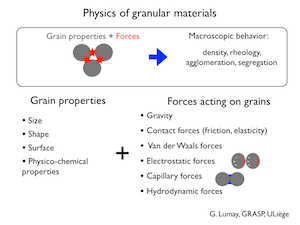

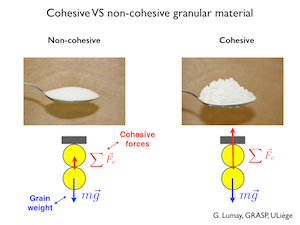

Physics of powders and granular materials. - A granular material is a conglomeration of discrete solid particles. Granular materials behavior is influenced by (1) steric repulsions, (2) friction forces (3) cohesive forces and (4) interaction with the surrounding gas. The steric repulsion is related to the grain geometry. Friction forces are influenced by both the surface state (rough or smooth surface) and the chemical nature of the grains. Cohesive forces may be induced by the presence of liquid bridges, by electrostatic charges, by van der Waals interactions or more rarely by magnetic dipole-dipole interactions. The predominance of one of these forces depends on both the environmental conditions and the physico-chemical properties of the grains. When the weight of one grain is higher than the cohesive forces, the material is considered as non-cohesive. These materials have been intensively studied during the last decades because of the rich variety of their physical properties. On the other hand, if the cohesive forces acting on a grain are higher than the weight of the grain, these cohesive forces will drastically modify the properties of the pile. Among these cohesive granular materials, fine powders are used in many research domains : chemistry, pharmacy, engineering... Nowadays, the processes used for the manipulation of powders are still mainly based on empirical knowledge. However, the complexity of the methods used in these domains induces the necessity of more rigorous knowledge of these materials. Therefore, fundamental studies of cohesive powders are still essential.

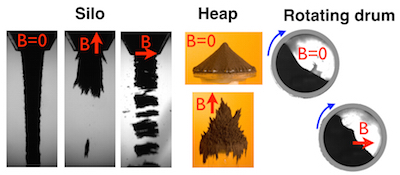

Model cohesive powders. - The difficulty to quantify and to control cohesion between the grains of a powder makes their experimental study very complex. Therefore, we first used a controlled cohesive powder made of metallic grains in an adjustable magnetic field B [18, 21]. In this controlled system, the cohesion between the grains can the tuned easily through the magnetic field. This system has been used during to study the influence of the cohesion on packing fraction, repose angle, heap shape, flow in silos and on the flow in a rotating drum.

Real cohesive powders. - After the study of model cohesive powders with a fundamental approach, we analyzed (and are still analyzing) the behavior of powders used in the industry with a more practical approach [25]. For that, we developped a range of original set-ups to measure packing dynamics, powder rheology, powder electrostatic properties, cohesiveness,... At the beginning, these set-ups were laboratory prototypes. After repetitive expressions of interest from industries, these methods were adapted to become commercial laboratory instruments:

GranuFlow,

GranuPack,

GranuDrum,

GranuHeap,

GranuMidity

and GranuCharge. These instruments are now commercialized by the company GranuTools.

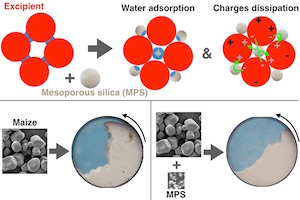

Combined effect of humidity and electrostatic charges on powders. - When two materials are rubbed, electric charges are exchanged at the surfaces. This contact electrification is an old fundamental scientific subject. However, despite the numerous studies dedicated to this subject, the fundamental mechanisms behind the triboelectric effect are not fully understood in powders and granular materials. The electric charges created by triboelectric effects lead to uncontrolled electric field, electrostatic forces between the grains and/or between the grains and the container. Moisture is known to affect both static and dynamic behaviors of granular materials. Moreover, the effect of moisture is far from obvious due to the interplay with electrostatic effects. Indeed, moisture influences both surface grains conductivity and capillary bridges formation. For low relative air humidity, the electrical conductivity necessary for charge dissipation is reduced. For high relative air humidity, the electrical conductivity increases and liquid bridges may be formed at the contacts between the grains, resulting in sticking. Therefore, the electrical charges are dissipated more easily. However, the apparition of liquid bridges also induces cohesive forces inside the packing. At intermediate relative humidity values the cohesion is expected to be lower. We performed different studies on that topic. In particular, we analyzed the effect of powder flow aid additives (fumed silica, mesoporous silica, stearate, ...) on these cohesive forces.

Self assembly processes - My present research project includes a second axis dedicated to the study of self-assembly processes leading to the formation of mesostructures. Mesostructures are microscopic (typically from 100 nanometers to 100 microns) architectures with complex arrangements which confer them remarkable physical properties. Static and dynamic properties of such structures are investigated using model systems of Soft Matter. This activity is based on expertise acquired during my experimental works on collective motions, and patterning in granular materials. These self-organization processes take place in assemblies of micro and nano particles placed in an external field (magnetic and/or electric) and submitted to geometrical, mechanical, capillary and hydrodynamic constraints. In order to identify and to control the relevant self-assembly processes, the interactions between the particles have to be studied precisely. With a better fundamental understanding of these interactions, the self-organization processes will be obtained through a bottom-up method instead of the classical empirical methods. Then, we will be able to improve the long-range organization in mesostructures, catalyst, porous materials, sintered materials, ... Moreover, future studies will be dedicated to reversible self-organized systems where the order could be modified in order to obtain smart reconfigurable materials.

Publications

1. Compaction of anisotropic granular materials: Experiments and simulations

Phys. Rev. E

70, 051314

(2004)

Show Abstract

2. Grain mobility and hexagonal domains formation in 2d granular compaction

Powders & Grains

1, 343

(2005)

Show Abstract

3. Experimental Study of Granular Compaction Dynamics at Different Scales: Grain Mobility, Hexagonal Domains, and Packing Fraction

Phys. Rev. Lett.

95, 028002

(2005)

Show Abstract

|  |

|---|

4. Experimental study of the compaction dynamics for two-dimensional anisotropic granular materials

Phys. Rev. E

74, 021301

(2006)

Show Abstract

5. Compaction of granular materials: experiments and contact dynamics simulations

J. Phys.: Conf. Ser.

40, 133

(2006)

Show Abstract

6. Linking compaction dynamics to the flow properties of powders

Appl. Phys. Lett.

89, 093505

(2006)

Show Abstract

7. Precursors to avalanches in a granular monolayer

Phys. Rev. E

74, 031311

(2006)

Show Abstract

8. The influence of grain shape, friction and cohesion on granular compaction dynamics

Eur. Phys. J. E

22, 241

(2007)

Show Abstract

9. Kinetic Energy Fluctuations and Diffusivity in a 2D Vibrated Granular Packing

TRAFFIC AND GRANULAR FLOW 2007

, 597

(2007)

Show Abstract

10. TUNABLE RANDOM PACKINGS

New J. of Phys.

9, 406

(2007)

Show Abstract

11. Swarming and swirling in self-propelled polar granular rods

Phys. Rev. Lett.

100, 058001

(2008)

Show Abstract

|  |

|---|

12. Stationary states in 1D system of inelastic particles

Ukr. Journ. Phys.

53, 1128

(2008)

Show Abstract

13. Controlled flow of Smart Powders

Phys. Rev. E

78, 061302

(2008)

Show Abstract

14. Mullite coatings on ceramic substrates: stabilisation of Al2O3-SiO2 suspensions for spray drying of composite granules suitable for reactive plasma spray

J. of Eur. ceramic soc.

29, 2169

(2008)

Show Abstract

15. Motion of carbon nanotubes in a rotating drum: The dynamic angle of repose and a bed behavior diagram

Chem. Eng. J.

146, 143

(2009)

Show Abstract

16. Packing fraction and compaction dynamics of magnetic powders

AIP Conf. Proc.

1145, 131-134

(2009)

Show Abstract

17. Flow properties and heap shape of magnetic powders

AIP Conf. Proc.

1145, 135-138

(2009)

Show Abstract

18. Compaction dynamics of a magnetized powder

Phys. Rev. E

80, 041302

(2009)

Show Abstract

19. Effect of an electric field on an intermittent granular flow

Phys. Rev. E

81, 041309

(2010)

Show Abstract

20. Compaction dynamics of wet granular assemblies

Phys. Rev. Lett.

105, 048001

(2010)

Show Abstract

21. Flow of magnetized grains in a rotating drum

Phys. Rev. E

82, 040301(R)

(2010)

Show Abstract

22. A pendulum test as a tool to evaluate viscous friction parameters in the equine fetlock joint

The Veterinary Journal

188, 204

(2011)

Show Abstract

23. Influence of a reduced gravity on the volume fraction of a monolayer of spherical grains

Phys. Rev. E

84, 041305

(2011)

Show Abstract

24. Granular gas in a periodic lattice

Eur. Phys. J. E

32, 1465

(2011)

Show Abstract

25. Measuring the flowing properties of powders and grains

Powder Technology

224, 19

(2012)

Show Abstract

26. How relative humidity affects random packing experiments

Phys. Rev. E

85, 031309

(2012)

Show Abstract

27. Hysteretic behavior in three-dimensional soap film rearrangements

Phys. Rev. E

83, 021403

(2011)

Show Abstract

28. Symmetry breaking in a few-body system with magnetocapillary interactions

Phys. Rev. E

85, 041402

(2012)

Show Abstract

29. Cascade of flows for characterizing segregation of granular mixtures

Powder Technology

234, 32

(2013)

Show Abstract

30. Breaking arches with vibrations: the role of defects and friction

Phys. Rev. Lett.

109, 068001

(2012)

Show Abstract

31. Flow abilities of powders and granular materials evidenced from dynamical tap density measurement

Powder Technology

235, 842

(2013)

Show Abstract

32. Experimental study of a vertical column of grains submitted to a series of impulses

European Physical Journal E

36, 16

(2013)

G. Lumay, S. Dorbolo, O. Gerasymov & N. Vandewalle

We report physical phenomena occurring in a vertical Newton's cradle system. A dozen of metallic spheres are placed in a vertical tube. Therefore, the gravity induces a non-uniform pre-compression of the beads and a restoring force. An electromagnetic hammer hits the bottom bead at frequencies tuned between 1 and 14 Hz. The motion of the beads are recorded using a high-speed camera. For low frequencies, the pulses travel through the pile and expel a few beads from the surface. Then, after a few bounces of these beads, the system relaxes to the chain of contacting grains. When the frequency is increased, the number of fluidized beads increases. In the fluidized part of the pile, adjacent beads are bouncing in opposition of phase. This phase locking of the top beads is observed even when the bottom beads experience chaotic motions. While the mechanical energy increases monotically with the bead vertical position, heterogeneous patterns in the kinetic energy distribution are found when the system becomes fluidized.

Hide Abstract

33. Influence of the gravity on the discharge of a silo

Granular Matter

15, 263

(2013)

Show Abstract

. Self-assembled magnetocapillary swimmers

Soft Matter

9, 2420

(2013)

Show Abstract

35. Melting of a confined monolayer of magnetized beads

Phys. Rev. E

87, 062201

(2013)

Show Abstract

36. Mesoscale structures from magnetocapillary self-assembly

Eur. Phys. J. E

36, 127

(2013)

Show Abstract

37. Customizing mesoscale self-assembly with three-dimensional printing

New J. of Phys.

16, 023013

(2014)

Show Abstract

38. Quantitatively mimicking wet colloidal suspensions with dry granular media

Scientific reports

5, 10348

(2015)

Show Abstract

39. Bernal random loose packing through freeze-thaw cycling

Phys. Rev. E

92, 010202

(2015)

Show Abstract

40. Rheological behavior of β-Ti and NiTi powders produced by atomization for SLM production of open porous orthopedic implants

Powder Technology

283, 199

(2015)

Show Abstract

41. Linking flowability and granulometry of lactose powders

International Journal of Pharmaceutics

494, 312

(2015)

Show Abstract

. Remote control of self-assembled microswimmers

Scientific reports

5, 16035

(2015)

Show Abstract

43. Flow of magnetic repelling grains in a two-dimensional silo

Papers in Physics

7, 070013

(2015)

Show Abstract

44. Ribbons of superparamagnetic colloids in magnetic field

The European Physical Journal E

39, 47

(2016)

Show Abstract

45. Statics and dynamics of magnetocapillary bonds

Phys. Rev. E

93, 053117

(2016)

Show Abstract

46. Effect of relative air humidity on the flowability of lactose powders

Journal of Drug Delivery Science and Technology

35, 207

(2016)

Show Abstract

47. Magnetoelastic instability in soft thin films

The European Physical Journal E

40, 29

(2017)

Show Abstract

48. Relating Brownian motion to diffusion with superparamagnetic colloids

American Journal of Physics

85, 265

(2017)

Show Abstract

49. Frustrated crystallization of a monolayer of magnetized beads under geometrical confinement

Phys. Rev. E

95, 062120

(2017)

Show Abstract

50. Self-assembly processes of superparamagnetic colloids in a quasi-two-dimensional system

Phys. Rev. E

96, 012608

(2017)

Show Abstract

51. Superparamagnetic colloids in viscous fluids

Scientific Reports

7, 7778

(2017)

Show Abstract

52. Self-assembly of smart mesoscopic objects

The European Physical Journal E

40, 108

(2017)

Show Abstract

53. Discharge of repulsive grains from a silo: experiments and simulations

EPJ Web of Conferences

140, 03089

(2017)

Show Abstract

54. Combined effect of moisture and electrostatic charges on powder flow

EPJ Web of Conferences

140, 13009

(2017)

Show Abstract

55. Transitional bulk-solutal Marangoni instability in sessile drops

Phys. Rev. E

98, 062609

(2018)

Show Abstract

56. Remote-controlled deposit of superparamagnetic colloidal droplets

Phys. Rev. E

98, 062608

(2018)

Show Abstract

57. Decompaction of wet granular materials under freeze-thaw cycling

Phys. Rev. E

99, 012901

(2019)

Show Abstract

58. From jamming to fast compaction dynamics in granular binary mixtures

Scientific Reports

9, 7281

(2019)

Show Abstract

59. Tribo-electrification of pharmaceutical powder blends

Particulate Science and Technology

37, 1020

(2019)

Show Abstract

60. How to gain a full understanding of powder flow properties, and the benefits of doing so

ONdrugDelivery

102, 42

(2019)

Show Abstract

61. Influence of mesoporous silica on powder flow and electrostatic properties on short and long term

Journal of Drug Delivery Science and Technology

53, 101192

(2019)

Show Abstract

62. Combined effects of Marangoni, sedimentation and coffee-ring flows on evaporative deposits of superparamagnetic colloids

Colloid and Interface Science Communications

32, 100198

(2019)

Show Abstract

63. Effect of volume fraction on chains of superparamagnetic colloids at equilibrium

European Physical Journal E

42, 123

(2019)

Show Abstract

|