Cohesive granular materials

Among the variety of granular materials, two categories should be considered separately: the non cohesive and the cohesive granular materials (see insert 1). Several recent works reported that cohesive forces affect the static, the quasistatic and the flow properties of powders. In order to study the influence of cohesive interactions between the grains on the macroscopic properties of granular assemblies, we have studied a "model system". The granular material, we investigated, is made of ferromagnetic grains submitted to a magnetic field B. By varying the strength of the field, the interparticle forces can be tuned continuously (see Insert 2). We checked that, within the magnetic values we considered (B < 100 G), the spheres are characterized by a nearly zero remanence. Therefore, after switching off the magnetic field, the cohesion inside the packing is expected to vanish.

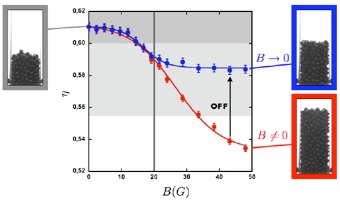

Our first study concerns the packing fraction of a cohesive pile. We have found that the packing fraction of a ferromagnetic pile created in a magnetic field exhibits "memory effects" when the magnetic field is swiched off (see and insert 4). We should note that the magnetic remanence is negligible in the range of magnetic field strength used in our study. Therefore, this «memory effect» is not related to a remanent magnetization of the grains. From that result, it is possible to create experimentally a pile of spheres with a selected packing fraction. To obtain more details about this study, see the open access publication NJP 2007.

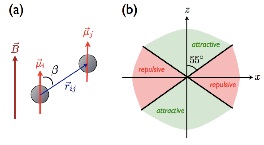

(a) Interactions between two ferromagnetic particles in a magnetic field B. The μ vector denotes the magnetic dipole induced by the magnetic field B, rij denotes the vector between the dipoles. (b) The magnetization of two ferromagnetic particles in a vertical magnetic field induces repulsive interaction when rij is perpendicular to B and attractive interaction when rij is parallel to B.

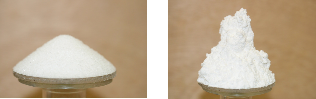

Both pictures represent a heap of sugar. In the left picture, the size of the grains is around 0.5 mm. In this case, the shape of the heap is fixed by the geometry of the grains and and by the frictional forces between the grains. When the grains size is smaller than typically 50 μm, the cohesive forces related to the humidity, to the electric charges and to the Van der Waals interactions become higher than the weight of one grain. Then, the cohesive forces influence strongly the macroscopic properties of the heap.

Process involving granular materials are omnipresent in the industry. Moreover, the energy cost necessary to handle granular material is generally higher than the energy necessary to manipulate liquid or gas. Therefore, at the worldwide scale, a better understanding of the granular properties could avoid the waste of a huge quantity of energy.

Insert 1: The cohesion

Insert 2: The magnetically induced cohesion.

The two pictures represent a heap made of 2 mm metallic grains. In the left picture, the heap has been formed without magnetic field. When a magnetic field is applied vertically (see right picture), the induced cohesion between the grains modify strongly the shape of the heap. A similarity is observed between this magnetic cohesion and the cohesion in the powder sugar (see insert 1).

Insert 3: The effect of the magnetical cohesion

B

B = 0

The magnetically induced interactions between the particles are expected to change significantly the internal structure of the packing and the forces network. Therefore, the macroscopic properties of a pile are strongly modified by the magnetic field (see insert 3). We have made different experiments to quantify the influence of the interactions at the scale of the grains on the macroscopic properties of a granular pile.

(in red) Packing fraction ηB as a function of the applied magnetic field B (expressed in gauss). (in blue) Packing fraction ηB→0 after switching off the magnetic field. Error bars are indicated. The dark gray region denotes the usual RCP values, while the light gray region represents settling (RLP) experiments. The vertical line at B = 20 G corresponds to the situation for which the magnetic force between two contacting grains along the magnetic field is equal to the weight of a grain. Snapshots of the upper grains, just above the coils illustrate the changes of the packing arrangements.

Insert 4: Packing fraction of magnetized grains

The compaction dynamics of a "magnetic" pile submitted to successive taps depends strongly on a the Bond number Bo which is the ratio between the cohesive magnetic force and the grain weight. The characteristic compaction time is found to increases as the square root of the Bond number. While the asymptotic packing fraction decreases as the inverse of the Bond number. The case of mixture of metallic and glass beads has also been investigated. A simple mesoscopic model based on the formation of granular chains along the magnetic field direction is proposed to explain the observed macroscopic properties of the packings. To obtain more details about this study, see the publication PRE 2009.

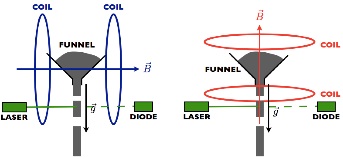

With the same model cohesive granular material, very particular flows have been observed at the output of a silo. Depending on the orientation of B, different dynamical regimes can be obtained like a «dry liquid state» forming conical droplets as well as a «layered soft state» (see insert 5). Scaling laws are given for the flow rate outside a funnel as a function of B and for the stopping threshold of the flow as a function the the funnel output diameter D. From this analysis, it appears that the flowing properties are related to the dimensionality of the magnetic aggregates. To obtain more details about this study, see the publication PRE 2008.

Introduction

Packing fraction

Flow

Insert 5: Flow outside a silo

B

B

B = 0

Three movies of the granular flow for different situations. (left) The cohesiveless case B=0. (center) The magnetic field B is parallel to gravity and the clusters are seen to be vertical needle-like. A dry droplet, having a nearly conical shape, is observed to fall free. (right) The magnetic field B is perpendicular to the gravity and the clusters are organised such that a horizontal layered structure is seen in the flow.

In this page, we present briefly our recent research dedicated to cohesive granular materials.

The compaction process can be used to measure the flowability of a «real» powder. Indeed, as shown by our fundamental studies, the characteristic compaction time could be related directly to the cohesion between the grains in a packing. The feasibility of this measurement has been proved in a collaboration with pharmacist. To obtain more details about this study, see the publication Applied Physics Letter 2006. An automatic apparatus has been developed to perform a compaction measurement easily and reliably with a powder. This apparatus is used in the platform APTIS dedicated to the powder characterization.

Posters presented at the conference «Powder And Grains 2009», Denver, USA

Publication

Publication

Publication